cross-referenced news and research resources about

RepRap open-source 3D printers

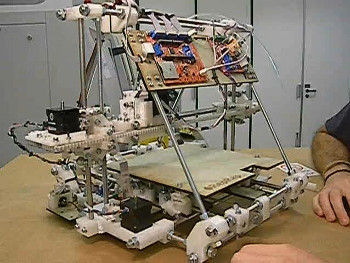

The RepRap project is an initiative to develop a 3D printer that can print most of its own components. RepRap (short for replicating rapid prototyper) uses a variant of fused deposition modeling, an additive manufacturing technique. The project calls it Fused Filament Fabrication (FFF) to avoid trademark issues around the "fused deposition modeling" term.

As an open design, all of the designs produced by the project are released under a free software license, the GNU General Public License.

To date, the RepRap project has released four 3D printing machines: "Darwin", released in March 2007, "Mendel", released in October 2009, "Prusa Mendel" and "Huxley" released in 2010. Developers have named each after famous biologists, as "the point of RepRap is replication and evolution".

Due to the self-replicating ability of the machine, authors envision the possibility to cheaply distribute RepRap units to people and communities, enabling them to create (or download from the Internet) complex products without the need for expensive industrial infrastructure (distributed manufacturing) including scientific equipment. They intend for the RepRap to demonstrate evolution in this process as well as for it to increase in number exponentially.

|

|

|

updated Mon. February 5, 2024

-

Hackaday

March 29, 2018

Most of the documentation for this build is hanging around on the RepRap forums, but the bulk of the work is already done. The first half of this build — the SCARA arm — is well-traveled territory for the RepRap community, and where there's some fancy math and kinematics going on, there's nothing too farÃâà...

3ders.org (blog)

March 29, 2018

... the RepRap of 3D bioprinters? Mar 29, 2018 | By Benedict. Researchers from Adam Feinberg's lab at Carnegie Mellon University have developed an open-source 3D bioprinter that can be built affordably using a modified desktop 3D printer. The large-volume extruder (LVE) component of the bioprinter can be 3D printed.

3D Printing Industry

March 28, 2018

The East Coast RepRap Festival will be coming to the Maryland/Delaware area in the summer of 2018! This event is inspired by the beloved MidWest RepRap Festival also known as MRRF. We will be inviting you, the 3D Printing community, to come and exhibit your 3D Printers with us, from small and simple to large andÃâà...

Hackaday

March 28, 2018

The last three days marked the 2018 Midwest RepRap Festival. Every year, the stars of the 3D printing world make it out to Goshen, Indiana for the greatest gathering of 3D printers and printing enthusiasts the world has ever seen. This isn't like any other 3D printing convention — everyone here needs toÃâà...

3DPrint.com

March 27, 2018

To say that open source is a major part of 3D printing would be an understatement in the extreme; indeed, to many, the open source RepRap Project is the most significant thing to come from 3D printing. Celebrating all things rooted in RepRap is the annual Midwest RepRap Festival (MRRF), hosted inÃâà...

Hackaday

March 26, 2018

For the last few years, the Replicape has been the board you need to plug a BeagleBone into a few motors. Now, there's a better, cheaper solution. At the Midwest RepRap Festival this weekend, [Elias Bakken] has unveiled the Revolve, a single board that combines Octavo Systems' OSD3358 'BeagleBoneÃâà...

3DPrint.com

March 26, 2018

It's the home of Midwest RepRap Festival (MRRF), the biggest gathering of the RepRap community in the world. As soon as we stepped through the doors at the Elkhart County 4-H Fairgrounds, the energy was obvious – and so was the level of knowledge and talent among the exhibitors busily setting upÃâà...

Hackaday

March 25, 2018

E3D has introduced their latest answer to multimaterial printing at the Midwest RepRap Festival this weekend. Their research project into a 3D printer with the ability to change toolheads is the latest advancement in multimaterial printing. It's a work of engineering brilliance, and they've already written upÃâà...

Hackaday

March 25, 2018

Perhaps one day our robot overlords will look back on all of the trivial things that humans made them do and take retribution on us. Until then, though, there's no problem having them perform all of our chores. [v.loschiavo] is also exploiting our future rulers and built a robot that mows his lawn automaticallyÃâà...

All3DP 3D Printing News

March 22, 2018

Debuting at the 2018 Midwest RepRap Festival this weekend is a tool changing 3D printer from British company E3D. This is a multi-material FFF machine that's quick, nimble, and very very clever. Don't Miss: E3D Releases Titan Aqua Water-Cooling System for FDM Printing. After weeks of teasing, the bright-eyed boffins atÃâà...

Hackaday

March 22, 2018

What time is it? It's Midwest RepRap Festival time, and it's happening this weekend in beautiful Goshen, Indiana. It's free, it's open to everyone, and it's the greatest 3D printer convention on Earth. What's so great about MRRF? This is where the latest products in the 3D printing space are launched. A fewÃâà...

Canadian Metalworking

March 8, 2018

Bossard Group, a Switzerland-based fastener technology and logistics company, has signed partnership agreements with three 3-D printing companies, including metal additive manufacturing (AM ) system provider TRUMPF, German RepRap, and stereolithography company Henkel. Through theÃâà...

3DPrint.com

March 7, 2018

This past fall, BCN3D Technologies, based out of Barcelona and best-known for its Sigma 3D printer, released the multi-material Sigmax 3D printer at the TCT Show. The professional desktop Sigmax, which features a large 420 x 297 x 210 mm build volume, uses FFF technology and is based on theÃâà...

3DPrint.com

March 7, 2018

This past fall, BCN3D Technologies, based out of Barcelona and best-known for its Sigma 3D printer, released the multi-material Sigmax 3D printer at the TCT Show. The professional desktop Sigmax, which features a large 420 x 297 x 210 mm build volume, uses FFF technology and is based on theÃâà...

3DPrint.com

March 6, 2018

For fused filament fabrication, Bossard will be working with German RepRap. The German company has been developing FFF 3D printers since 2013, and offers six different models ranging from the compact X150 to the large format X1000. Its customers are a diverse group, including industrial companies,Ãâà...

3D Printing Industry

March 6, 2018

Bossard (SWX:BOSN), a Swiss fastener technology and logistics group, is entering the additive manufacturing market as a supplier for three established 3D printing industry names. Partnered with TRUMPF, German RepRap and Henkel, the Bossard group and it's subsidiary KVT-Fastening corners threeÃâà...

3ders.org (blog)

March 5, 2018

Bossard Group, a Swiss fastener technology and logistics company, has signed partnership agreements with three 3D printing companies including metal AM specialist TRUMPF, German RepRap, and stereolithography company Henkel. Through the partnerships, Bossard Group says it will supplyÃâà...

3ders.org (blog)

March 5, 2018

Bossard Group, a Swiss fastener technology and logistics company, has signed partnership agreements with three 3D printing companies including metal AM specialist TRUMPF, German RepRap, and stereolithography company Henkel. Through the partnerships, Bossard Group says it will supplyÃâà...

3ders.org (blog)

February 6, 2018

RepRap 3D printing engineers Michael Simpson and Simon Khoury have carried out a scientific study into the use of cheap piezoelectric elements for ... is now commonplace amongst even lower-end FDM 3D printers, building your own bed leveling system remains a challenge for many RepRap users.

3DPrint.com

July 26, 2017

When the RepRap project began, it was almost by necessity that the machines were required to self-improve. Several limitations in path planning and motion control at the time had limited the performance and reliability of the machines. Prints were slow, and the generated GCode often had incorrectÃâà...

Hackaday

December 31, 1999

Most of the documentation for this build is hanging around on the RepRap forums, but the bulk of the work is already done. The first half of this build — the SCARA arm — is well-traveled territory for the RepRap community, and where there's some fancy math and kinematics going on, there's nothing too farÃâà...

3ders.org (blog)

December 31, 1999

Researchers from Adam Feinberg's lab at Carnegie Mellon University have developed an open-source 3D bioprinter that can be built affordably using a modified desktop 3D printer. The large-volume extruder (LVE) component of the bioprinter can be 3D printed. This open-source bioprinting system can beÃâà...

Hackaday

December 31, 1999

E3D has introduced their latest answer to multimaterial printing at the Midwest RepRap Festival this weekend. Their research project into a 3D printer with the ability to change toolheads is the latest advancement in multimaterial printing. It's a work of engineering brilliance, and they've already written upÃâà...

3ders.org (blog)

December 31, 1999

The metal 3D printer itself is based on an open-source design reportedly inspired by the Rostock delta RepRap printer, only it integrates a gas metal arc welding (GMAW)-based print head, making metal 3D printing possible. The open-source metal 3D printer can reportedly be made for as little as $1,200.

Torque-Expo

December 31, 1999

Bossard Group has teamed up with three partners for its move into the emerging market of 3D printing. Cooperation partners for the Swiss market include TRUMPF (laser metal fusion), German RepRap (fused filament fabrication) and Henkel (stereolithography). These partnerships will allow Bossard to sellÃâà...

|

news and opinion

|

|

|

|

|

|